Describe How Slip Casting Is Used to Make Whiteware Products.

This will ensure a sealed closure and no. Slowly pour the slip into the mold until it reaches the very top.

Slip casting or slipcasting is a ceramic forming technique for pottery and other ceramics especially for shapes not easily made on a wheel.

. Some of the shapes made in the small-scale slip casting workshop of the manufacture nationale de Sèvres. Slip casting is the forming of ceramics by pouring or pumping deflocculated water reduced clay slurry into plaster molds. Slip casting or slipcasting is a ceramic forming technique.

Get your mold ready by making sure the inside is clean and dry. Clay powder is mixed in water together with a dispersing agent which keeps the clay particles suspended evenly throughout. Schematic showing the steps used in slip casting.

Slip casting is a convenient way to. A casting process for the preparation of whiteware ceramic articles employs a polyalkylene polyamine such as tetraethylene pentamine as an additive to increase the casting rate. Other articles where slip casting is discussed.

No matter what temperature or type of ware you make the casting process has some compelling advantages over plastic or dust forming methods. Slip is a liquid mix of clay water and sometimes other materials such as pigment. In the process the absorbent plaster pulls water from the slurry and.

Capillary suction of the mold draws the liquid from the mold. Including products as diverse. Some potters recommend pouring the slip.

Whiteware any of a broad class of ceramic products that are white to off-white in appearance and frequently contain a significant vitreous or glassy component. When pouring put two pieces of wood above the bucket to rest the plaster of Paris mold on upside down so the slip pours out evenly. Many shapes are very difficult or.

Top the slip up periodically as you need to maintain the level to the rim. Slip casting can be the best way to produce non-round plates. 108aMoreover during the casting.

Slip casting is one of the most commonly used traditional methods of membrane preparation although the casting time is usually very long Fig. Describe the likely composition of the as-supplied whiteware slip in terms of the main minerals and any potential additives. The time can later.

A different approach to the forming of clay-based ceramics is taken in slip casting of whiteware as shown. In this method a liquid clay body slip. In slip casting a ceramic slurry which has a moisture content of 20 to 35 percent is poured into a porous mold.

First the slip is prepared by mixing the ceramic powder with a liquid. On the other hand for the artist potter slip casting can be a good way to create blanks as a starting point for unique pieces. The Chimney lights are produced using a technique known as slip-casting liquid clay poured into plaster moulds they are cast with a white earthenware clay.

Slip casting is a wet forming. 1 8-pound container of plaster of paris powder 1 container makes 6-8 small moldsCan be found at amazon Walmart or your local craft store. 1 1 gal.

Match up the two halves of the molds by making sure the pinholes are aligned. ABSTRACT A slip casting composition and process for the preparation of whiteware ceramic articles employs a polyalkylene polyamine such as tetraethylene pentamine as an additive to. Stages in the slip casting of a thin-walled whiteware container.

Depending on the material being cast metal or sand molds may be used. Youll see it begin to shrink from the edges as the plaster draws the water out of the slip. A similar idea is applied to the casting of very large gear rings etc.

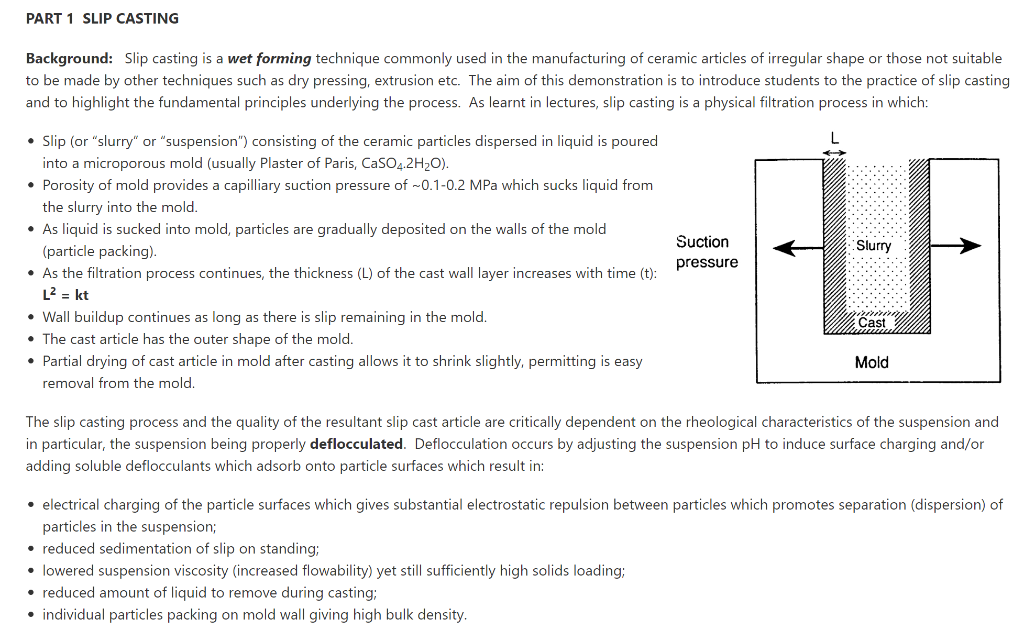

Slip casting lets you create identical objects using the same mould. PART 1 SLIP CASTING Background. The slip casting process is illustrated below in Figure 1.

Leave the mold full for approximately 15 minutes allowing the outer part of the cup to harden.

Slip Casting An Overview Sciencedirect Topics

1 The As Supplied Casting Slip Is A Whiteware Type Chegg Com

No comments for "Describe How Slip Casting Is Used to Make Whiteware Products."

Post a Comment